Did you know that up to 30 percent of construction costs can stem from rework due to design clashes and poor coordination? That’s where Ingebim comes in, an engineering-led approach to Building Information Modeling (BIM) that’s changing how we build smarter, more resilient structures.

Ingebim puts engineering at the heart of BIM, blending structural expertise with digital tools to create intelligent systems that go beyond basic 3D models. If you’re an architect, civil engineer, project manager, or BIM coordinator, this methodology offers a path to streamlined workflows and better project outcomes. Let’s dive into what makes it tick.

Ingebim, short for engineering-led BIM, flips the script on traditional modeling by prioritizing structural integrity and system intelligence from the start. Unlike standard BIM, which often starts with architectural design, Ingebim begins with engineering principles to ensure every element supports the project’s core needs, like load-bearing capacity and long-term durability.

Think of it this way: in a typical setup, you might model a bridge’s aesthetics first and tweak the engineering later. With Ingebim, engineers lead the charge, integrating parametric design and structural analysis early on. This creates a foundation where digital twins, virtual replicas of physical assets, can simulate real-world performance before a single beam is placed.

Why does this matter in the AEC industry? Projects are getting more complex, with demands for sustainability and efficiency. Ingebim addresses that by fostering interoperability between tools and teams, reducing silos that lead to errors. For instance, companies like IngeBIM specialize in this, helping infrastructure firms cut risks and boost collaboration.

At its foundation, Ingebim rests on a few key ideas that make it powerful for digital transformation.

Engineering Priority: Everything starts with structural analysis. Engineers use data-driven models to test scenarios, ensuring designs handle real stresses like seismic activity or heavy traffic.

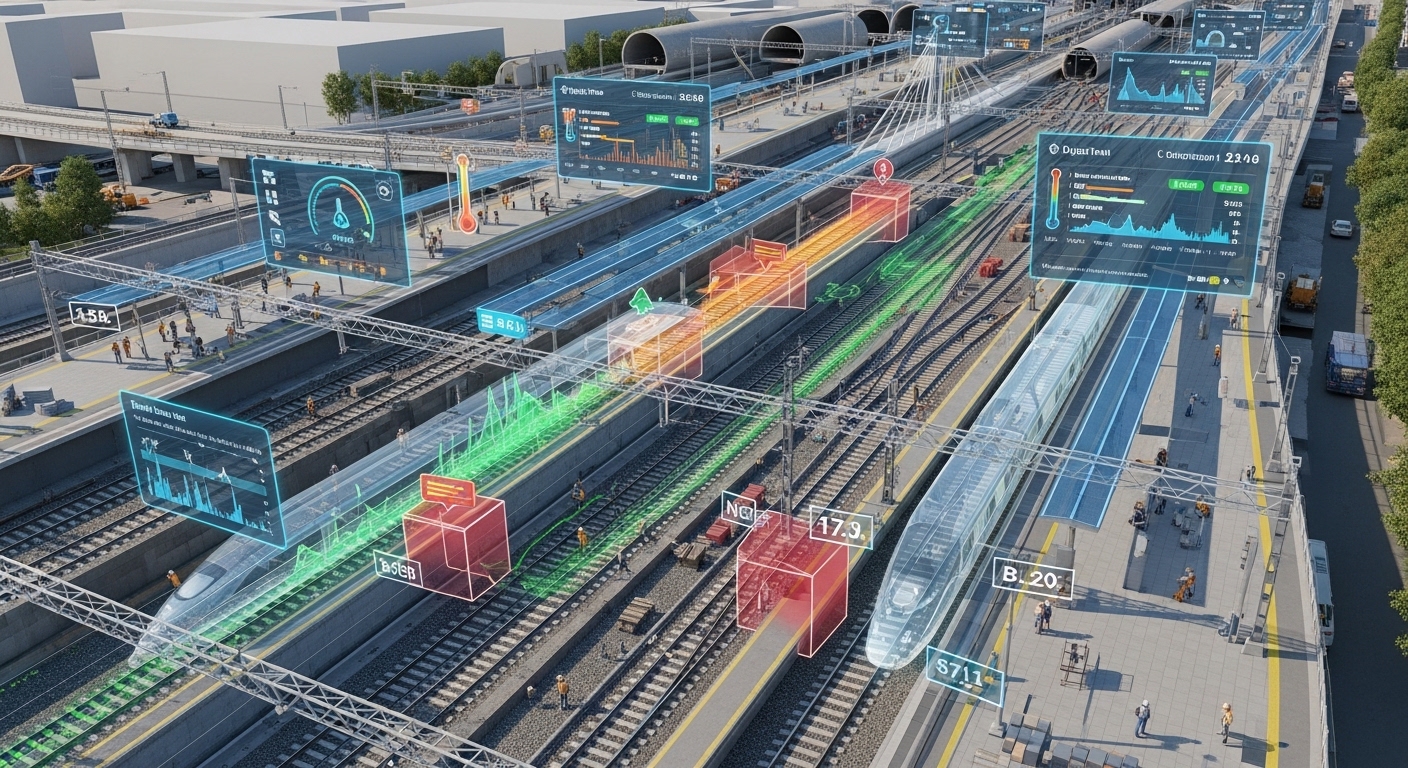

Intelligent Integration: This isn’t just about 3D visuals. Ingebim incorporates digital twins for lifecycle management, allowing ongoing monitoring from construction to maintenance.

Modularity and Efficiency: Designs break into reusable modules, perfect for modular construction. This speeds up assembly and cuts waste, as seen in large-scale projects where prefabricated parts snap together seamlessly.

Clash Detection and Interoperability: Advanced tools spot conflicts early, like piping clashing with beams. By using open standards, Ingebim ensures software from different vendors talks to each other without hiccups.

These principles turn BIM from a drawing tool into a strategic asset, optimizing workflows in ways that save time and money.

Civil engineers stand to gain a lot from Ingebim, especially in tackling everyday challenges like budget overruns and delays.

First off, it enhances accuracy. By leading with engineering, models catch issues early, potentially reducing rework by 15 to 20 percent, according to industry studies. Imagine designing a highway where structural analysis flags weak points before excavation starts, that’s real savings.

Collaboration gets a boost too. Teams share a single, intelligent model, making coordination smoother. Project managers can track changes in real time, avoiding the back-and-forth that plagues traditional methods.

Then there’s cost efficiency. Ingebim’s focus on modularity means parts are prefabricated off-site, shortening on-site timelines. For civil projects, this could trim construction time by up to 25 percent, freeing up resources for other tasks.

Sustainability is another win. Digital twins help simulate energy use and material impacts, supporting greener choices. In one case, a railway project used Ingebim to optimize track layouts, cutting material needs by 10 percent while improving safety.

You might wonder if the upfront investment pays off. It does, with many firms reporting positive ROI through fewer errors and faster delivery.

Large-scale infrastructure, like bridges or tunnels, demands precision at every turn, and Ingebim shines here.

Take railways: Ingebim allows engineers to model entire networks, integrating geotechnical data with structural elements. A Toronto tunnel project, for example, used this approach to simulate soil interactions, avoiding costly surprises during digging.

For highways, parametric design lets teams adjust variables like traffic flow or environmental factors on the fly. This modularity makes scaling easier, whether expanding lanes or adding smart sensors for real-time monitoring.

Benefits include better risk management. Clash detection prevents overlaps in complex systems, like utilities under roads. Plus, lifecycle management through digital twins extends asset life, predicting maintenance needs years ahead.

In places like New York or Sweden, firms applying Ingebim to bridges have seen improved interoperability, blending architectural flair with rock-solid engineering.

If you’re handling mega-projects, Ingebim turns potential headaches into efficient, scalable solutions.

Getting started with Ingebim doesn’t have to be overwhelming. Here’s a step-by-step guide to bring these intelligent systems into your workflow.

Assess Your Needs: Start by auditing current processes. Identify pain points, like coordination gaps or outdated tools. For BIM coordinators, this means checking team skills in structural analysis.

Choose the Right Tools: Opt for software that supports interoperability, such as Autodesk Revit with add-ons for digital twins. Integrate parametric design features to make models adaptive.

Train Your Team: Invest in workshops on engineering-led BIM. Focus on clash detection and modularity to build confidence.

Pilot a Project: Test on a smaller scale, like a modular building component. Monitor efficiency gains, adjusting as needed.

Scale and Iterate: Roll out to larger projects, using data from digital twins to refine approaches. Track metrics like time saved or errors reduced.

Common mistakes to avoid: Skipping engineering input early or ignoring interoperability standards. Address doubts head-on, data shows these systems cut costs over time.

Real companies, like those in Chile or Europe, have implemented Ingebim for urban infrastructure, seeing smoother handoffs between design and construction phases.

Revit is a powerhouse for BIM, but how does it stack up against Ingebim workflows?

Revit excels in 3D modeling and parametric design, letting users create detailed elements quickly. However, it’s often architect-focused, with engineering as an add-on.

Ingebim shifts that, making engineering the driver. While Revit might handle clash detection, Ingebim integrates it with structural analysis for deeper insights.

In workflows, Revit is great for standalone designs, but Ingebim promotes team-wide interoperability, reducing silos. For example, in a civil engineering project, Revit might model a structure, but Ingebim ensures it’s optimized for lifecycle management via digital twins.

The edge? Ingebim adds intelligence, turning models into predictive tools. If you’re used to Revit, layer Ingebim principles on top for hybrid efficiency.

Let’s bring this to life with scenarios.

In railway modeling, Ingebim lets engineers create parametric tracks that adjust for terrain. A Canadian project used it to simulate train loads, spotting weak spots early and saving millions in fixes.

Digital twins take it further. For a UAE urban development, a twin mirrored the physical site, allowing remote monitoring during construction. This caught a clash in utility lines, preventing delays.

In modular construction, Ingebim’s efficiency shines. Prefab modules for a Swedish bridge were designed with interoperability in mind, assembling like Lego for faster build times.

These examples show Ingebim isn’t abstract, it’s practical for optimizing real workflows.

No methodology is perfect. Initial costs for training and software can deter teams, but long-term savings outweigh them.

Data security is another concern with digital twins. Use robust protocols to protect sensitive info.

Team resistance? Start small, showing quick wins like reduced clashes.

By addressing these, Ingebim becomes a game-changer for forward-thinking pros.

In wrapping up, Ingebim offers a roadmap to smarter construction through engineering-led BIM. It optimizes workflows, cuts risks, and paves the way for sustainable projects.

Next steps: Evaluate your tools, train on key principles, and pilot a project. What’s one shift you’ll make to embrace this future?

You May Also Like: Serlig Explained: The Digital Framework You Didn’t Know You Needed

What is Ingebim?

Ingebim is an engineering-led methodology in Building Information Modeling that emphasizes structural integrity and intelligent integration for better project outcomes.

How does Ingebim differ from standard BIM?

While BIM focuses on modeling, Ingebim prioritizes engineering from the outset, incorporating digital twins and parametric design for enhanced efficiency.

What are the key benefits for civil engineers?

It reduces rework, improves collaboration, and supports lifecycle management, leading to cost savings and faster project delivery.

Can Ingebim work with existing tools like Revit?

Yes, it enhances Revit workflows by adding engineering focus and interoperability for more intelligent designs.

Is Ingebim suitable for small projects?

Absolutely, its modularity scales well, making it efficient even for smaller modular constructions.

How does Ingebim support sustainability?

Through digital twins and optimized designs, it minimizes waste and simulates energy use for greener outcomes.

What’s the first step to implement Ingebim?

Assess your team’s needs and start with training on engineering-led principles.